Tensile testing

Tensile testing, is also known as tension testing,[1] is a fundamental materials science test in which a sample is subjected to a controlled tension until failure. The results from the test are commonly used to select a material for an application, for quality control, and to predict how a material will react under other types of forces. Properties that are directly measured via a tensile test are ultimate tensile strength, maximum elongation and reduction in area.[2] From these measurements the following properties can also be determined: Young's modulus, Poisson's ratio, yield strength, and strain-hardening characteristics.[3] Uniaxial tensile testing is the most commonly used for obtaining the mechanical characteristics of isotropic materials. For anisotropic materials, such as composite materials and textiles, biaxial tensile testing is required.

Tensile specimen

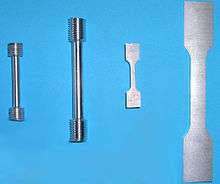

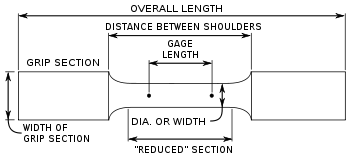

A tensile specimen is a standardized sample cross-section. It has two shoulders and a gage (section) in between. The shoulders are large so they can be readily gripped, whereas the gauge section has a smaller cross-section so that the deformation and failure can occur in this area.[2][4]

The shoulders of the test specimen can be manufactured in various ways to mate to various grips in the testing machine (see the image below). Each system has advantages and disadvantages; for example, shoulders designed for serrated grips are easy and cheap to manufacture, but the alignment of the specimen is dependent on the skill of the technician. On the other hand, a pinned grip assures good alignment. Threaded shoulders and grips also assure good alignment, but the technician must know to thread each shoulder into the grip at least one diameter's length, otherwise the threads can strip before the specimen fractures.[5]

In large castings and forgings it is common to add extra material, which is designed to be removed from the casting so that test specimens can be made from it. These specimens may not be exact representation of the whole workpiece because the grain structure may be different throughout. In smaller workpieces or when critical parts of the casting must be tested, a workpiece may be sacrificed to make the test specimens.[6] For workpieces that are machined from bar stock, the test specimen can be made from the same piece as the bar stock.

A. A Threaded shoulder for use with a threaded grip

B. A round shoulder for use with serrated grips

C. A butt end shoulder for use with a split collar

D. A flat shoulder for used with serrated grips

The repeatability of a testing machine can be found by using special test specimens meticulously made to be as similar as possible.[6]

A standard specimen is prepared in a round or a square section along the gauge length, depending on the standard used. Both ends of the specimens should have sufficient length and a surface condition such that they are firmly gripped during testing. The initial gauge length Lo is standardized (in several countries) and varies with the diameter (Do) or the cross-sectional area (Ao) of the specimen as listed

| Type specimen | United States(ASTM) | Britain | Germany |

|---|---|---|---|

| Sheet ( Lo / √Ao) | 4.5 | 5.65 | 11.3 |

| Rod ( Lo / Do) | 4.0 | 5.00 | 10.0 |

The following tables gives examples of test specimen dimensions and tolerances per standard ASTM E8.

| All values in inches | Plate type (1.5 in. wide) | Sheet type (0.5 in. wide) | Sub-size specimen (0.25 in. wide) |

|---|---|---|---|

| Gauge length | 8.00±0.01 | 2.00±0.005 | 1.000±0.003 |

| Width | 1.5 +0.125–0.25 | 0.500±0.010 | 0.250±0.005 |

| Thickness | 0.188 ≤ T | 0.005 ≤ T ≤ 0.75 | 0.005 ≤ T ≤ 0.25 |

| Fillet radius (min.) | 1 | 0.25 | 0.25 |

| Overall length (min.) | 18 | 8 | 4 |

| Length of reduced section (min.) | 9 | 2.25 | 1.25 |

| Length of grip section (min.) | 3 | 2 | 1.25 |

| Width of grip section (approx.) | 2 | 0.75 | 3⁄8 |

| All values in inches | Standard specimen at nominal diameter: | Small specimen at nominal diameter: | |||

|---|---|---|---|---|---|

| 0.500 | 0.350 | 0.25 | 0.160 | 0.113 | |

| Gauge length | 2.00±0.005 | 1.400±0.005 | 1.000±0.005 | 0.640±0.005 | 0.450±0.005 |

| Diameter tolerance | ±0.010 | ±0.007 | ±0.005 | ±0.003 | ±0.002 |

| Fillet radius (min.) | 3⁄8 | 0.25 | 5⁄16 | 5⁄32 | 3⁄32 |

| Length of reduced section (min.) | 2.5 | 1.75 | 1.25 | 0.75 | 5⁄8 |

Equipment

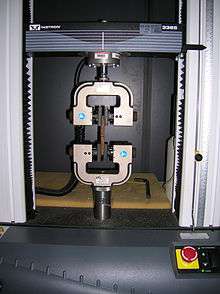

The most common testing machine used in tensile testing is the universal testing machine. This type of machine has two crossheads; one is adjusted for the length of the specimen and the other is driven to apply tension to the test specimen. There are two types: hydraulic powered and electromagnetically powered machines.[4]

The machine must have the proper capabilities for the test specimen being tested. There are four main parameters: force capacity, speed, precision and accuracy. Force capacity refers to the fact that the machine must be able to generate enough force to fracture the specimen. The machine must be able to apply the force quickly or slowly enough to properly mimic the actual application. Finally, the machine must be able to accurately and precisely measure the gauge length and forces applied; for instance, a large machine that is designed to measure long elongations may not work with a brittle material that experiences short elongations prior to fracturing.[5]

Alignment of the test specimen in the testing machine is critical, because if the specimen is misaligned, either at an angle or offset to one side, the machine will exert a bending force on the specimen. This is especially bad for brittle materials, because it will dramatically skew the results. This situation can be minimized by using spherical seats or U-joints between the grips and the test machine.[5] If the initial portion of the stress–strain curve is curved and not linear, it indicates the specimen is misaligned in the testing machine.[8]

The strain measurements are most commonly measured with an extensometer, but strain gauges are also frequently used on small test specimen or when Poisson's ratio is being measured.[5] Newer test machines have digital time, force, and elongation measurement systems consisting of electronic sensors connected to a data collection device (often a computer) and software to manipulate and output the data. However, analog machines continue to meet and exceed ASTM, NIST, and ASM metal tensile testing accuracy requirements, continuing to be used today.

Process

The test process involves placing the test specimen in the testing machine and slowly extending it until it fractures. During this process, the elongation of the gauge section is recorded against the applied force. The data is manipulated so that it is not specific to the geometry of the test sample. The elongation measurement is used to calculate the engineering strain, ε, using the following equation:[4]

where ΔL is the change in gauge length, L0 is the initial gauge length, and L is the final length. The force measurement is used to calculate the engineering stress, σ, using the following equation:[4]

where F is the tensile force and A is the nominal cross-section of the specimen. The machine does these calculations as the force increases, so that the data points can be graphed into a stress–strain curve.[4]

Standards

Metals

- ASTM E8/E8M-13: "Standard Test Methods for Tension Testing of Metallic Materials" (2013)

- ISO 6892-1: "Metallic materials. Tensile testing. Method of test at ambient temperature" (2009)

- ISO 6892-2: "Metallic materials. Tensile testing. Method of test at elevated temperature" (2011)

- JIS Z2241 Method of tensile test for metallic materials

Flexible materials

- ASTM D638 Standard Test Method for Tensile Properties of Plastics

- ASTM D828 Standard test method for tensile properties of paper and paperboard using constant-rate-of-elongation apparatus

- ASTM D882 Standard test method for tensile properties of thin plastic sheeting

- ISO 37 rubber, vulcanized or thermoplastic—determination of tensile stress–strain properties

References

- ↑ Czichos, Horst (2006). Springer Handbook of Materials Measurement Methods. Berlin: Springer. pp. 303–304. ISBN 978-3-540-20785-6.

- 1 2 Davis, Joseph R. (2004). Tensile testing (2nd ed.). ASM International. ISBN 978-0-87170-806-9.

- ↑ Davis 2004, p. 33.

- 1 2 3 4 5 Davis 2004, p. 2.

- 1 2 3 4 Davis 2004, p. 9.

- 1 2 Davis 2004, p. 8.

- 1 2 Davis 2004, p. 52.

- ↑ Davis 2004, p. 11.