Iore

| |||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||

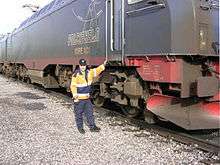

Iore, often stylized IORE, is a class of 34 electric locomotives built by Adtranz and its successor Bombardier Transportation for the Swedish mining company LKAB's railway division Malmtrafik. The class is a variation of Adtranz's Octeon modular product platform, thus related to Bombardier's later TRAXX platform. The locomotives haul iron ore freight trains on the Iron Ore Line and Ofoten Line in Sweden and Norway, respectively. The 8,600-tonne (8,500-long-ton; 9,500-short-ton) 68-car trains are hauled by two single-ended Co′Co′ locomotives, each with a power output of 5,400 kW (7,200 hp). Each operates with 600 kilonewtons (130,000 pounds-force) tractive effort and has a maximum speed of 80 km/h (50 mph). Delivery of the first series of 18 locomotives was made from 2000 to 2004, and they replaced some of the aging Dm3 and El 15 units. In 2007, eight more vehicles (4 double units) were ordered, with production to be completed by 2011, by which time, another four double units were ordered. These units are scheduled to be delivered from 2013 to 2014.

History

The Ofoten Line and the Iron Ore Line are two railroad lines which were built to allow iron ore to be hauled from the LKAB's mines in Kiruna, Svappavaara and Malmberget in Sweden to Luleå on the Baltic Sea in Sweden and to Narvik on the Norwegian Sea in Norway.[4] Historically, these lines were operated by the Norwegian State Railways (NSB) in Norway and the Swedish State Railways (SJ) in Sweden, but in 1996 the operations, but not the infrastructure, were transferred to the new company Malmtrafik i Kiruna (MTAB), a joint venture between LKAB, NSB and SJ, and its Norwegian subsidiary Malmtrafikk (MTAS).[5] At the time, the line was using El 15 and Dm3 locomotives.[6]

In 1998, LKAB estimated a steady 35% increase in iron ore production until 2005, and requested that the governments grant sufficient funding to upgrade the lines from 25-tonne (25-long-ton; 28-short-ton) to 30-tonne (30-long-ton; 33-short-ton) maximum permitted axle load. Combined with new locomotives, this would give increased efficiency in hauling the ore from the mines.[7] The upgrade was estimated to cost 180 million Norwegian krone (NOK) for the Ofoten Line alone.[8]

In March 1998, LKAB awarded the contract to build 750 new 100-tonne hopper cars to Transnet of South Africa.[9] In August, an agreement was reached whereby LKAB would pay NOK 100 million of the NOK 130 million needed to upgrade the Ofoten Line.[10] The contract to deliver 18 locomotives was signed with Adtranz Switzerland[11] on 15 September 1998.[12] In 1999, LKAB bought SJ's and NSB's share in MTAB.[13][14]

The first two sections were delivered by Adtranz in August 2000,[2] and was subjected to intensive tests before the manufacture of the rest of the series.[11] Commissioning concluded in December 2000,[1] the locomotive started regular service on 10 January 2001,[11] and started operation with the new hopper cars and 30-tonne (30-long-ton; 33-short-ton) axle load on 7 March 2001.[15] In May 2001, Bombardier Transportation took over Adtranz.[16] Bombardier delivered the rest of the Iore series from 2002 to 2005.[1] In March 2004, LKAB decided not to purchase additional hopper cars from Transnet, and instead purchased 750 heavier cars from K-Industrier.[4] Since 1969, the ore trains have been using the Soviet SA3 coupler. However, LKAB wanted to also try Janney couplers (also known as AAR coupler, used in much heavier trains in USA and South Africa), as the SA3 couplers were not much tested with the new weights.[17] While the first pair of locomotives had Janney couplers, the rest of the locomotives were equipped with SA3 couplers to handle the existing hopper cars, and the cars bought from K-Industrier. The locomotives and Transnet wagons with Janney couplers were retrofitted with SA3 couplers. In 2004, the El 15 locomotives were sold to Hector Rail.[18]

On 23 August 2007, LKAB ordered another four twin units, with delivery in 2010 and 2011, and costing €52 million.[19] These will replace all remaining Dm3 locomotives by 2011, and LKAB convert all the ore trains to 68 cars.[20] This will increase the capacity from 28 to 33 million tonnes per year, and at the same time reduce the number of departures per day from 21 to 15.[21]

The name Iore is a mixture between the term Iron ore, and the fictional character Eeyore from Winnie-the-Pooh, spelled I-or in Swedish.

Specifications

The Iore class was a cold-adapted and heavy-haul derivation from Adtranz's Octeon modular electric locomotive platform,[11][14] which was launched in 1998 on the basis of Adtranz's latest models for Deutsche Bahn at the time.[22] Adtranz and later Bombardier Transportation conducted the final assembly of the locomotives at Kassel, Germany.[11] When Bombardier Transportation introduced the brand name TRAXX for its updated modular locomotive platform, the type designation TRAXX H80 AC was applicable to the Iore class,[23] however, it was excluded from the TRAXX family by the time of the second batch order in 2007.[24] The manufacturer has also referred to the locomotive type as the Bombardier Kiruna.[25]

Each Iore consists of twin units with one driver's cab at each. They normally operate in fixed units of two, making a pair capable of hauling a 8,600-tonne (8,500-long-ton; 9,500-short-ton) ore train. Technically an Iore section is also capable to operate as single locomotive, an option that is seldom used in operation.[26] The units are fed with 15 kV 16 2⁄3 Hz AC via a pantograph. The power is transformed and then converted via a single water-cooled gate turn-off (GTO) thyristor based converter per bogie. The converters belong to the Camilla family,[27] which was developed by ABB's Swiss branch as successor for its oil-cooled converters,[28] and found previous use in the FS Class E464.[29] The converters operate independently, with their own cooling and control systems and are shut down automatically in case of failure. The converters consist of seven line-replaceable unit modules to minimize maintenance costs. Each locomotive has six three-phase asynchronous alternating current traction motors, each rated at 918 kW (1,231 hp) and each powering a single axle.[30] This gives a Co′Co′ wheel arrangement. The tractive effort of each locomotive is 600 kN (130,000 lbf) and the maximum dynamic braking effort is 375 kN (84,000 lbf).[1] There is also a boost function, allowing a temporary traction effort of 700 kN (160,000 lbf).[3] The units are capable of 80 km/h (50 mph) in single runs, 70 km/h (43 mph) with empty trains and 60 km/h (37 mph) with loaded trains.[2]

The locomotives are 22.905 m (75 ft 1.8 in) long, 4.465 m (14 ft 7.8 in) tall and 2.950 m (9 ft 8.1 in) wide. The distance between the bogie centers is 12.890 m (42 ft 3.5 in) and the bogie wheel-base is 1.920 m (6 ft 3.6 in). The wheel diameter is 1.250 m (4 ft 1.2 in) when new and 1.150 m (3 ft 9.3 in) when worn. Each locomotive weighs 180 tonnes (180 long tons; 200 short tons), of which 38 tonnes (37 long tons; 42 short tons) is electrical equipment.[1] Each locomotive has 30 tonnes (30 long tons; 33 short tons) of dead weight to increase the locomotive's weight to the maximum axle weight, and further weight increase has been achieved by making the walls 4 centimetres (1.6 in) wide with armored steel.[3] The extra wall thickness also provides for increased structural strength, to withstand collisions with snowdrifts and elk.[11] The sides of the walls were built as flat as possible to reduce the sticking of blowing snow and ice formation.[11]

The auxiliary system is powered via a separate transformer winding feeding three independent insulated gate bipolar transistor (IGBT) converters each providing a three-phase 400 volt system. The locomotive is designed with an open system architecture that can be adapted later. Diagnostic information is available to the driver and can be sent to the control center via GSM-R.[1] The locomotive has a large and bright cab with space for up to three people. The second series of locomotives have an improved driver's chair, which has been retrofitted on the older trains. The machine room has a center hallway. All high-current equipment is located behind a door which can only be opened with a special key. This key is locked in such a way that it cannot be accessed without grounding the locomotive, and similarly the locomotive cannot be ungrounded again until the key is back in place.[3]

Operation

.png)

LKAB operates iron ore mines in Kiruna, Svappavaara and Malmberget in Norrbotten County, Sweden. Most of the output is transported by rail to the ice-free Port of Narvik, a route named the Northern Circuit. A minority of the ore is transported to Luleå on the Southern Circuit. Located on the Baltic Sea, ore is shipped to Baltic customers, or delivered to furnaces operated by SSAB in Luleå and Oxelösund. The Iron Ore and Ofoten Lines are 536 km (333 mi) long, including the branch to Svappavaara, with the route from Kiruna to Narvik being 170 km (110 mi), and from Malmberget to Luleå being 220 km (140 mi). Operations are handled by LKAB's subsidiary Malmtrafik i Kiruna (MTAB) in Sweden, and Malmtrafikk (MTAS) in Norway. As of 2010, six pairs of the first batch Iore locomotives[20] operate 11 to 13 trains daily in each direction on the Northern Circuit, and the remaining three pairs of the first batch[20] operate five to six trains on the Southern Circuit.[4] The four pairs of second-batch locomotives will replace Dm3 locomotives on the Northern Circuit by 2011.[20]

The trains hauled by Iore are 68 cars long and weigh 8,600 tonnes (8,500 long tons; 9,500 short tons).[31] From Riksgränsen on the national border to the Port of Narvik, the trains use only a fifth of the power they regenerate. The regenerated energy is sufficient to power the empty trains back up to the national border.[32] Although the trains and hopper cars are all owned by LKAB, the line is owned by the Swedish Transport Administration and the Norwegian National Rail Administration.[4] The Iron Ore and Ofoten Lines are also used by passenger and container trains.[33][34]

See also

- China Railways HXD3B: a single-section freight locomotive based on the Iore[25]

References

| Wikimedia Commons has media related to Iore. |

- 1 2 3 4 5 6 "Iore Locomotives". Bombardier Transportation. Archived from the original (PDF) on 25 October 2010. Retrieved 25 October 2010.

- 1 2 3 "Adtranz-Schwergewicht ausgeliefert". Eisenbahn Kurier (in German): 21. October 2000.

- 1 2 3 4 Stiberg, Trond (2008). "Iore". Lokomotivmands Tidende. National Union of Norwegian Locomotivemen (3): 14. Archived from the original (PDF) on 24 October 2010. Retrieved 24 October 2010.

- 1 2 3 4 "Logistics". LKAB. Archived from the original on 25 October 2010. Retrieved 25 October 2010.

- ↑ "MAlmtrafikk A/S blir Ofotbane-transportør" (in Norwegian). Norwegian News Agency. 9 May 1996.

- ↑ Nilsen, Knut A. (11 November 1996). "Ofotbanen – en privatisert koloss". Aftenposten (in Norwegian). p. 13.

- ↑ Markusson, Helge M. (7 February 1998). "Svensk malmgigant presser Norge". Nordlys (in Norwegian). p. 9.

- ↑ Nilsen, Geir Bjørn (26 January 1998). "Milliardsalg kan spore av i nord". Dagens Næringsliv (in Norwegian). p. 8.

- ↑ Markusson, Helge M. (3 March 1998). "Fikk ikke malmvogn-kontrakt av LKAB". Nordlys (in Norwegian). p. 9.

- ↑ "LKAB vil ruste opp Ofotbanen". Aftenposten (in Norwegian). 26 August 1998. p. 33.

- 1 2 3 4 5 6 7 "Erztransporte in Schweden – Neue Lokomotiven von Adtranz". Eisenbahn Kurier (in German): 28–29. July 2001.

- ↑ "LKAB med storkontrakt". Dagens Næringsliv (in Norwegian). 16 September 1998. p. 19.

- ↑ Markusson, Helge (15 May 1999). "Gir Ofotbanen til svenskene". Nordlys (in Norwegian). p. 8.

- 1 2 "Locos ordered". Railway Gazette International. October 1998. Retrieved 9 January 2011.

- ↑ "30 tonnes on the Malmbanan". Railway Gazette International. June 2001. Retrieved 9 January 2011.

- ↑ "Adtranz takeover completed". Railway Gazette International. June 2001. Retrieved 11 January 2011.

- ↑ Bergstedt, Rune (2004-01-18). "Automatkoppel" (in Swedish). Royal Institute of Technology. Archived from the original (PDF) on 25 October 2010. Retrieved 25 October 2010.

- ↑ "El 15 til Hector Rail". Ny Teknik (in Swedish). 29 November 2004.

- ↑ "Bombardier is Awarded an Additional Order for One of the World's Most Powerful Electrical Locomotives". Bombardier. 23 August 2007. Retrieved 11 January 2011.

- 1 2 3 4 "Investering i fyra nya linjelok och 222 malmvagnar". LKAB. Archived from the original on 25 October 2010. Retrieved 25 October 2010.

- ↑ "Går over til lengre – og færre – tog neste år". Fremover (in Norwegian). 15 February 2010. p. 4.

- ↑ "Adtranz launches off-the-shelf strategy". Railway Gazette International. May 1998. Retrieved 11 January 2011.

- ↑ "The New Name For Reliability. Bombardier TRAXX - the modular locomotive family". Bombardier. Archived from the original on 6 December 2003. Retrieved 9 January 2011.

- ↑ "Other Projects". Bombardier. Archived from the original on 19 April 2008. Retrieved 9 January 2011.

- 1 2 "China: Erste Bombardier-Lokomotive ausgeliefert" (in German). Eurailpress. 7 January 2009. Retrieved 11 January 2011.

- ↑ "MTAB IORE (Seite 3)" (in German). Retrieved 27 January 2011.

- ↑ "MTAB IORE (Technische Daten)" (in German). Retrieved 27 January 2011.

- ↑ "Hochleistungsstromrichter für Schienenfahrzeuge" (in German). Kipfer Development. Archived from the original on 2005. Retrieved 25 January 2011.

- ↑ "Optimised bearings for locomotive transmissions". Evolution. SKF. 2010-05-15. Retrieved 2011-01-09.

- ↑ http://www05.abb.com/global/scot/scot326.nsf/veritydisplay/b53e94802c75e541c125789a00290729/$file/Railvolution02-11-Traction-transformer-Kiruna.pdf

- ↑ "Fire nye: LKAB får levert fire slike lok. LKAB kjøper flere". Fremover (in Norwegian). 27 January 2010. p. 4.

- ↑ Næss, Per (3 August 2007). "Evighetsmaskiner". Fremover (in Norwegian). p. 28.

- ↑ "Et nettverk av godsterminaler" (in Norwegian). CargoNet. Retrieved 25 October 2010.

- ↑ "Narvik" (in Norwegian). Norwegian National Rail Administration. Retrieved 25 October 2010.