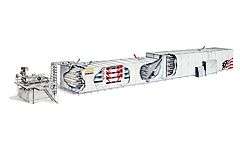

Dry pasta line

Dry pasta lines are machines that make dry pasta products such as spaghetti or penne. Commercial manufacturers use these machines for high volume production ranging from 500 kg to 8,000 kg per hour capacity. A typical dry pasta line consists of an extruder and a dryer.[1] Modern machines are highly automated using programmable logic controllers. They are called "lines" because they contain a series of processing machines lined up in a row.

Extruder

The extruder mixes flour and water to make dough, kneads the dough and pushes it through a die to form the shape, and cuts the pasta to the correct length. Dry pasta lines typically use rectangular dies to extrude long goods pasta and round dies to extrude short goods pasta. The extruder typically uses a vacuum system in the mixing process to keep air out of the dough.[1]

Dryer

The dryer dries the pasta to the correct moisture level, typically using sticks or screens to transport pasta inside the dryer depending on the length of the product. Long goods pasta such as spaghetti is hung vertically from sticks and short goods pasta such as penne is placed on long horizontal conveyors with mesh screen belts. Long goods pasta takes about 6-9 hours to dry depending on the temperature used in the drying process and short goods pasta takes about 3-4 hours. Air circulation, heat and moisture control are critical factors to the pasta drying process.

Post drying

Manufacturers can store and package pasta in many ways after drying.

See also

Notes

| Wikimedia Commons has media related to Dry pasta lines. |

- 1 2 Hoseney, R. Carl. Principles of Cereal Science and Technology, 2nd Edition (St. Paul, MN: American Association of Cereal Chemists, Inc., 1986, 1994 and second printing 1998), P. 325-26.