Chine (boating)

A chine in boating refers to a sharp change in angle in the cross section of a hull. A hull without chines has a gradually curving cross section. The term hard chine indicates an angle with little rounding, where a soft chine would be more rounded, but still involve the meeting of distinct planes. Chine log construction is a method of building hard chine boat hulls. Hard chines are common in plywood hulls, while soft chines are often found on fiberglass hulls.

Reasons for chines

The oldest type of engineered boats are dugout canoes, which were built by hollowing out a log. These designs generally had rounded bottoms, which made best use of the round shape of the logs. Traditional planked hulls in most cultures are built by placing wooden planks oriented parallel to the waterflow and attached to bent wooden frames. This also produced a rounded hull, generally with a sharp bottom edge to form the keel. Planked boats were built in this manner for most of history.

The first hulls to start incorporating hard chines were probably shallow draft cargo carrying vessels used on rivers and in canals. The barge and later the scow used a flat bottom and near vertical sides, which provided the maximum cargo carrying capacity (in both space and displacement) available for a given depth of water.

Once sufficiently powerful marine motors had been developed to allow powerboats to plane, it was found that the flat underside of a chined boat provided maximum hydrodynamic lift, while the sharp discontinuity at the chine enabled spray to be deflected away as opposed to riding up the sides of the boat. Consequently, almost all boats designed for high speed on the plane are nowadays of hard chine construction.

Sailing scows

The scow in particular, in the form of the scow schooner, was the first significant example of a hard chine sailing vessel. While the squared off scow hulls were ugly to sailors accustomed to the sleek, rounded hulls of the time, a scow could carry far more cargo, and while a laden scow was slow and difficult to sail, when not heavily laden it would keep up with the traditional schooners sailing to windward. While sailing scows had a poor safety reputation, that was due more to their typical cheap construction and tendency to founder in storms. As long as it sailed in the protected inland and coastal waters it was designed to operate in, however, the sailing scow was an efficient and cost effective solution to transporting goods from inland sources to the coast.[1] A good example of this is the gundalow.[2]

Steamboats

Working in the same inland waters as the sailing scows was the later river steamboat. River steamboats were often built using the same hard chined construction methods of the sailing scows, with a flat bottom, hard chine, and nearly vertical sides.[3]

Small boats

The punt is one of the older and simplest hard chine small boats. Consisting usually of a single plank for each side, with a square bow and stern, the punt was in essence a tiny scow. The sides of a punt are vertical, and they were typically propelled along shallow waters with a long pole, a method of propulsion referred to as punting. Punts are generally used for recreation, and are popular with duck hunters for their ability to move in marshy hunting areas.

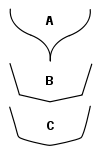

Various types of chine hulls

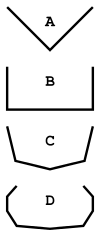

The simplest type of chine construction is the single chine "V" shape, with two flat panels joined at the keel (A). This type of hull is among the simplest to build, but they lack stability on a narrow "V" and may lack freeboard on a wide "V". Single chine hulls are generally only seen on multihull sailboats, which often use two deep "V" shaped hulls connected by akas to provide mutual stability.

The two chine hull (B), with a flat bottom and nearly vertical sides, was the first hard chine design to achieve widespread use. This design provides far more stability than the single chine hull, with minimum draft and a large cargo capacity. These characteristics make the two chine hull popular for punts, barges, and scows.

The three chine hull (C) is probably the most common hard chine hull. Having a shallow "V" in the bottom and near-vertical panels above that, it approximates the shape of traditional rounded hull boats fairly well. This hull is common, even in fiberglass designs where employing chines offers no advantage in construction.

Designs with higher numbers of chines (D), often just called multichine hulls, are also common. By increasing the number of chines, the hull can very closely approximate a round bottomed hull. Kayaks, in particular, are often composed of many chines, required for the complex shapes needed to provide good performance under various conditions.

It is possible to refer to the different hulls by the numbers of the flat panels that make up the boat. Thus A is a two-panel boat, B is a three-panel boat, C is a four-panel boat and D is an eight-panel boat.

Constructing a chined hull

Construction of a chined hull is subject to many different parameters than a round hull, both positive and negative:

- The sharp angles do not favor bent wooden frames

- The wide, flat panels may be cross-planked, where the planks may run perpendicular to the keel rather than parallel to it

- Planks may be of any width, not just a width small enough to approximate the curve of the hull, and most planks can be cut with square edges

- Flat sections do not provide the stiffness of a rounded section

Plank hulls

The limitations of wood plank construction, the desire to maximize cargo volume, and the quest for fast, easy hull building led to a new type of construction method unique to chined hulls. This new method used wooden supports placed along the chines called chine logs to provide strength where the chines joined. Beams are then attached to the chine log to support planks running parallel to the chine, while cross-planked sections such as a typical scow bottom may be attached directly to the chine log. This method of construction originated with the sailing scow[4] and continues to be used today, primarily in home built boats. Use of a chine log provides some structural support, but most chine log hulls are primarily monocoque in nature, with the hull planking itself bearing most of the structural load.

Chine log construction works best for hulls where the sides join a flat bottom at a right angle, but it can be used for other angles as well with an appropriately angled chine log. Builders of small boats such as punts, where the plank thickness is large compared to the size of the hull, can dispense with the chine log and nail intersecting planks directly into one another.

Plywood hulls

Plywood offers the builder a better "plank", far wider, thinner, and stronger than a simple wood plank. Ply is normally produced in 4' × 8' (1.2 m × 2.4 m) sheets or similar. It is normally joined lengthwise by an 1:8 scarf joint using epoxy resin glue. A chined hull built out of plywood will often be designed to keep most of the lengthwise joints between the plywood sheets at the chines, thus making the building process easier. While chine logs (often just called chines) can be used for plywood boats,[5] another common technique replaces the chine logs with a fiberglass and epoxy fillet joint that provides both connection and stiffness to the joint; this method is most commonly called stitch and glue construction. The result of the stitch and glue operation is a composite "chine log" with a much greater degree of flexibility in curvature and shape than is possible with a wooden chine log. Thinner ply panels, especially 4 mm, can be warped into compound bends to achieve arc bottom boats. This has the benefit of giving a more rounded section, with more displacement and in theory slightly higher speed. Additionally the bent ply is far stiffer than a flat ply panel, so needs less internal support, in the hull, in the form of frames or stringers. This further reduces weight giving a significant boost in performance and by clever design can be used to create a shape closer in appearance to a rounded hull but at far less cost.

Fiberglass hulls

Home-builders may use fiberglass to cover hulls built of plywood or a synthetic foam. These materials form the shape of the hull, and the fiberglass and resin is applied to this to provide more strength, especially impact or abrasion resistance to the hull. In this case the hull shape is determined by the core materials.

Commercial fiberglass hulls are molded, and since the fiberglass and resin used have no inherent shapes, the mold can be of just about any shape. The fibre glass is fired into the mold with a gun, normally using chop mat strands in epoxy. It is important to control the atmosphere to keep humidity low during this operation otherwise moisture may be trapped in the fibreglass that will eventually blister and cause fibreglass pox. Molds for low production power boats are often made of plywood, and so the properties of the plywood often result in a chined hull. Hard chines may be rounded off by the addition of filler to the mold to create a fillet; this creates the soft chines often found on fiberglass boats.The outside of a mold is supported by a steel lattice work to ensure rigidity.