CREAM

CREAM (Cognitive Reliability Error Analysis Method) is a human reliability analysis technique developed by Erik Hollnagel. It is a bi-directional analysis method, meant to be used for both performance prediction and accident analysis. Unlike first generation error analysis methods like THERP, CREAM represents a second generation tool allowing for better analysis by abandoning the hierarchical structure of previous methods and providing better separation between objective and subjective error.

CREAM is a technique used in the field of human reliability assessment (HRA), for the purposes of evaluating the probability of a human error occurring throughout the completion of a specific task. From such analyses measures can then be taken to reduce the likelihood of errors occurring within a system and therefore lead to an improvement in the overall levels of safety. There exist three primary reasons for conducting an HRA; error identification, error quantification and error reduction. As there exist a number of techniques used for such purposes, they can be split into one of two classifications; first generation techniques and second generation techniques. First generation techniques work on the basis of the simple dichotomy of ‘fits/doesn’t fit’ in the matching of the error situation in context with related error identification and quantification and second generation techniques are more theory based in their assessment and quantification of errors. HRA techniques have been utilised in a range of industries including healthcare, engineering, nuclear, transportation and business sector; each technique has varying uses within different disciplines.

CREAM is a second generation HRA method. However compared to many other such methods, it takes a very different approach to modelling human reliability. There are two versions of the technique, the basic and the extended version, both of which have in common two primary features; ability to identify the importance of human performance in a given context and a helpful cognitive model and associated framework, usable for both prospective and retrospective analysis. Prospective analysis allows likely human errors to be identified while retrospective analysis quantifies errors that have already occurred.

The concept of cognition is included in the model through use of four basic ‘control modes’ which identify differing levels of control that an operator has in a given context and the characteristics which highlight the occurrence of distinct conditions. The control modes which may occur are as follows:

- Scrambled control: the choice of the forthcoming action is unpredictable or haphazard. The situation in question may be portraying rapid alterations in unexpected ways thus eliminating the operator’s ability or opportunity to make deductions about the next action required.

- Opportunistic control: the next action is determined by superficial characteristics of the situation, possibly through habit or similarity matching. The situation is characterised by lack of planning and this may possibly be due to the lack of available time.

- Tactical control: performance typically follows planned procedures while some ad hoc deviations are still possible.

- Strategic control: plentiful time is available to consider actions to be taken in the light of wider objectives to be fulfilled and within the given context.

The particular control mode determines the level of reliability that can be expected in a particular setting and this is in turn determined by the collective characteristics of the relevant Common Performance Conditions (CPCs).

Background

CREAM was developed by Eric Hollnagel in 1998 following an analysis of the methods for HRA already in place. It is the most widely utilised second generation HRA technique and is based on 3 primary areas of work; task analysis, opportunities for reducing errors and possibility to consider human performance with regards to overall safety of a system.

The aim of utilising this methodology is to assist an analyst in four main areas:

- identify work, actions or tasks within the system which necessitate or essentially depend on human thinking and which are therefore vulnerable to variations in their level of reliability.

- identify the surrounding conditions in which the cognition of these situations may be reduced and therefore determine what actions may lead to a probable risk

- compile an evaluation from the assessment of the various outcomes of human performance and their effect on system safety – this can then be utilised as part of the probability risk assessment (PRA).

- make suggestions as to how identified error producing conditions may be improved and therefore of how the system’s reliability can be enhanced whilst also reducing risk.

Methodology

1. Task analysis

The basic method adopted by the CREAM technique provides an immediate reliability interval based on an assessment of the given control mode, as highlighted by the figures provided in the table below. As can be seen by the contents of the table, each of the specified control modes has an individual reliability level. In the extended CREAM version, the control modes play the role of a weighting factor which scales a nominal failure probability associated to a given cognitive function failure. This version of CREAM is intended to be used for the purposes of a more in depth analysis of human interactions.

| Control mode | Reliability interval (probability of action failures) |

|---|---|

| Strategic | 0.5 E-5 < p < 1.0 E-2 |

| Tactical | 1.0 E-3 < p < 1.0 E-1 |

| Opportunistic | 1.0 E-2 < p < 0.5 E-0 |

| Scrambled | 1.0 E-1 < p < 1.0 E-0 |

2. Context description

The intention of the basic CREAM method is to use it as a screening technique with the aim of identifying processes which require a deeper level of analysis; this analysis may then be carried out by the extended CREAM method.

3. Specification of initiating events

When using the basic CREAM method, a task analysis is conducted prior to further assessment. CPCs are assessed according to the descriptors, given in the below Table, in order to judge their expected effect on performance.

| CPC name | Level/descriptors | Expected effect on performance reliability |

|---|---|---|

| Adequacy of organisation | Very Efficient | Improved |

| Efficient | Not Significant | |

| Inefficient | Reduced | |

| Deficient | Reduced | |

| Working conditions | Advantageous | Improved |

| Compatible | Not significant | |

| Incompatible | Reduced | |

| Adequacy of MMI and operational support | Supportive | Improved |

| Adequate | Not Significant | |

| Tolerable | Not Significant | |

| Inappropriate | Reduced | |

| Availability of procedures/ plans | Appropriate | Improved |

| Acceptable | Not significant | |

| Inappropriate | Reduced | |

| Number of simultaneous goals | Fewer than capacity | Not significant |

| Matching current capacity | Not significant | |

| More than capacity | Reduced | |

| Available time | Adequate | Improved |

| Temporarily inadequate | Not significant | |

| Continuously inadequate | Reduced | |

| Time of day (circadian rhythm) | Day-time (adjusted) | Not significant |

| Night-time (unadjusted) | Reduced | |

| Adequacy of training and expertise | Adequate, high experience | Improved |

| Adequate, limited experience | Not significant | |

| Inadequate | Reduced | |

| Crew collaboration quality | Very efficient | Improved |

| Efficient | Not significant | |

| Inefficient | Not significant | |

| Deficient | Reduced |

4. Error prediction

The assessments of the CPCs then require to be adjusted according to some specified rules in order to take account of synergistic effects. The matrix above would be considered in the context of the situation under assessment and by this means the previously considered initiating events are reviewed with respect to how they could potentially lead to the occurrence of an error. The rows of the matrix identify the possible outcomes while the columns show the precursors. The analyst then has the task of identifying the columns for which all the rows have been similarly classified into the same group according to the column headings. Predicting the possible outcomes for each of the rows should be done until there are no remaining possible paths. Each of the identified errors requires to be noted along with the causes and the outcomes.

5.

Finally, a simple count is performed of the number of CPCs that are causing an improvement in reliability and those which are reducing it. On the basis of this number the probable control mode is determined, by judging the region given in the graph as depicted below.

6.

The extended version of the CREAM methodology operates in a slightly different manner. Following the initial task analysis, a refinement is then provided in terms of the cognitive activities which are involved in the considered task (classified as co-ordinate, communicate, compare, etc.). To these activities a Contextual Control Model (COCOM) function (observation, interpretation, planning and execution) is ascribed (following a table provided) so that a cognitive demand profile may be established.

7.

Following this stage, the probable cognitive function failures are identified, based on a knowledge of the specific tasks, yet following a set of generic cognitive function failures associated to the COCOM functions. Each of these generic failures is associated with a nominal probability which is based on a table given in CREAM. However these probabilities are adjusted depending on the particular control mode. Hence in the extended version of the CREAM methodology the control mode acts in the role of a Performance Shaping Factor with the task of performing adjustments to a nominal probability.

Provided below is a simplified diagrammatic representation of all the stages involved in the complete CREAM methodology.

Worked example

Context

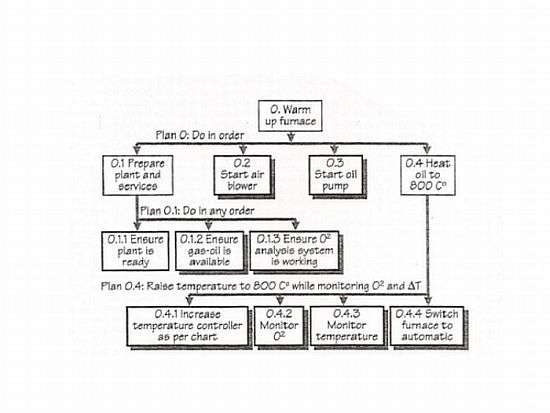

The basic example that is provided below concerns the task of ‘restarting a furnace following a system trip’. The following figure illustrates the hierarchical task analysis carried out for the task.

The overall task is made up of four basic tasks, which are further completed by carrying out a number of sub-tasks. First level tasks are required to be performed in the given sequence while the tasks on sub level two can be carried out in any order. Finally the lowest level tasks are conducted as necessary in a repetitive manner.

Assumptions

In this example, a number of assumptions should be noted in order to aid understanding. It is assumed that the warm-up task does not have any procedural support nor is it one that has been trained in detail.

Required inputs

From study of the task analysis, it is then possible to identify the necessary activities of the overall task that must be carried out.

This involves assessing the work conditions under which the task in question is performed. These are judged and rated on a scale as can be seen in the table provided below:

| CPC name | Evaluation |

|---|---|

| Adequacy of Organisation | The quality of the support and resources provided by the organisation for the task or work being performed. This includes communication systems, Safety Management System, support for external activities etc. |

| Descriptors | Very efficient/ Efficient/ Inefficient / Deficient |

| Working conditions | The conditions under which the work takes place, such as ambient lighting, glare on screens, noise from alarms, interruptions from the task etc. |

| Descriptors | Advantageous/ Compatible /Incompatible |

| Adequacy of MMI and operational support | The quality of the MMI and/or specific operational support provided for operators. The MMI includes control panels, workstations, and operational support provided by specifically designed decision aids |

| Descriptors | Supportive/ Adequate/ Tolerable /Inappropriate |

| Availability of procedures/plans | The availability of prepared guidance for the work to be carried out, including operating/ emergency procedures, routines & familiar responses |

| Descriptors | Appropriate/ Acceptable/ Inappropriate |

| Number of simultaneous goals | The number of tasks or goals operators must attend to. Since the number of goals is variable, this CPC applies to what is typical/characteristic for a situation. |

| Descriptors | Fewer than capacity/ Matching current capacity /More than capacity |

| Available Time | The time available to complete the work; or the general level of time pressure for the task and the situation type. How well the task is synchronised to the process dynamics. |

| Descriptors | Adequate /Temporarily inadequate /Continuously inadequate |

| Time of day (circadian rhythm) | The time at which the task is carried out, in particular whether the person is adjusted to the current time. |

| Descriptors | Day-time(adjusted) /Night-time (unadjusted) |

| Adequacy of training and preparation | The level of readiness for the work as provided (by the organisation) through training and prior instruction. Includes familiarisation to new technology, refreshing old skills, etc. as well as the level of operational experience |

| Descriptors | Adequate, high experience/ Adequate, limited experience/ Inadequate |

| Crew collaboration quality | The quality of the collaboration between crew members, including the overlap between the official and unofficial structure, the level of trust, and the general social climate among crew members. |

| Descriptors | Very efficient/ Efficient / Inefficient / Deficient |

Method

In order to calculate the combined CPC score, the assigned ratings of the CPCs are entered in the table as shown in step 3 of the methodology section. Using certain rules [19]an assessment is made as to whether it is necessary to adjust the CPCs. In this example this is not necessary. Therefore the combined CPC score for this example is [3,5,1]. This is interpreted as the CPC’s pointing to a reduced performance reliability, 4 CPC’s indicate that there is no significant influence and 1 CPC suggests an improved performance reliability.

Result

By determining the most likely control mode for the example, the general action failure probability can also thus be identified. Referring to the graphical display in Figure 1, the result for this example is that the operator is expected to be in an opportunistic control mode. This adequately relates to the assumption provided earlier that the operator under consideration has only slight experience or training for the task and there is insufficient support for the operations involved in the task. It may therefore be suggested that the operator may task a ‘try and test’ approach, particularly for complicated tasks such as increasing the temperature under controlled conditions.

The last stage of the process is to determine the probability interval for the expected control mode, the opportunistic control mode. Referring to table 1, for this example, the general action failure probability is within the range of 1.0 E-2 < p < 0.5 E-0. As this is not regarded as an acceptable there is no clear and justified reason to continue with the analysis being undertaken.

Advantages

- the technique allows for the direct quantification of human error probability (HEP)

- it also allows the assessor using the CREAM method to specifically tailor the use of the technique to the contextual situation [2]

- the resultant model is highly integrate-able into the primary safety process in use

- the technique uses the same principles for retrospective and predictive analyses [2]

- the approach is very concise, well structured and follows a well laid out system of procedure [2]

Disadvantages

- the technique requires a high level of resource use, including lengthy time periods for completion[2]

- CREAM also requires an initial expertise in the field of human factors (HF) in order to use the technique successfully and may therefore appear rather complex for an inexperienced user[2]

- CREAM does not put forth potential means by which the identified errors can be reduced[2]

- The time required for application is very lengthy

References

[1] Hollnagel, E. (1998). Cognitive Reliability and Error Analysis Method – CREAM. Oxford: Elsevier Science.

[2] Stanton, N. A., Salmon, P. M., Walker, G. H., Baber, C. & Jenkins, D. P (2005) Human Factors Methods: A Practical Guide for Engineering and Design. Ashgate: Aldershot.

[3] XuHong, He (2005). "A simplified CREAM prospective quantification process and its application". Reliability Engineering & Safety System. 93, 298-306.

[4] Kim, I.S. (2001). "Human reliability analysis design review". Annals of Nuclear Energy. 28, 1069-1081.